Aquality’s Aqua-Recycling-Control

Above Ground System

1| Coarse filter with back wash facility

2| Greywater buffer tank collects the incoming water for treatment

3| Aerator supplies water with oxygen and keeps membranes free from dirt deposits

4| Membrane filter guarantees the high water quality

5| Clear water storage keeps water available for use

6| Aqua Recycling-Control monitors and controls the treatment process

7| Aqua-Control booster pump set with mains water back-up facility and controls

8| Floor drain is needed as a safety measure

Operation

The greywater is filtered/treated in three controlled stages in the Aqua-Recycling-Control (ARC) system. First the water passes a coarse filtration stage in order to separate larger dirt particles (hair etc). Then, the water enters the aerobic treatment buffer tank. Here, the incoming water is collected and aerated. Next, in the membrane tank the water is passes through the BMT-Membrane and is lifted to the clear water storage tank. From the clear water storage tank the water is pumped via the Aqua-Control booster pump set to the serviced appliances. If no treated greywater is available or the tanks are undergoing maintenance the Aqua-Control will change to mains water back-up using a WRAS compliant air gap.

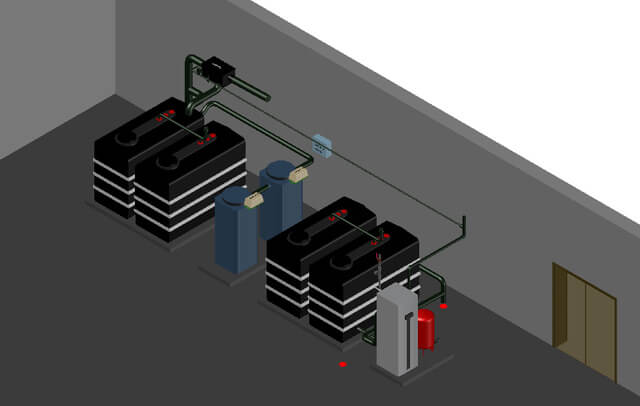

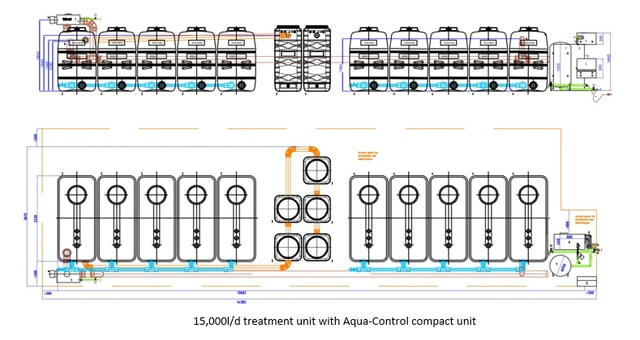

Installation Examples

The Aquality greywater systems are very flexible in design, due to their modular construction. Moreover, they use little space to treat significant amounts of water. Here are just two examples of possible plant room configurations:

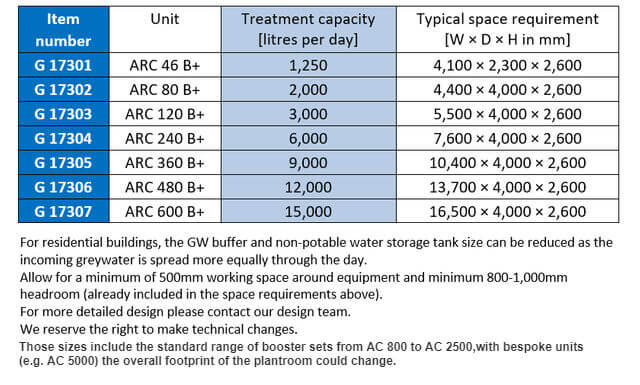

The table below gives space requirements in standard plant layout, for a first idea on space requirements.

The arrangement can be customised for various plant room layouts.

To receive project-specific design guidance or to request a meeting with one of our experienced design engineers simply click through to our online questionnaire.